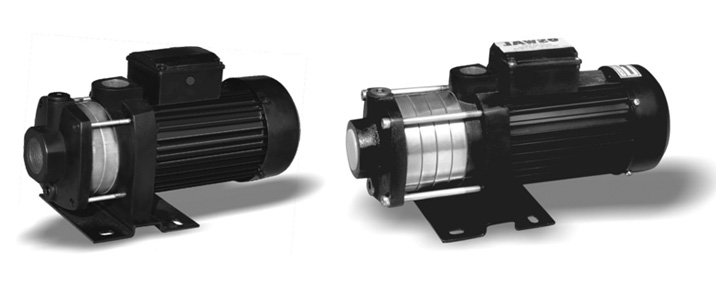

Horizontal Multistage Centrifugal Pumps

OCH Horizontal Multistage Booster Pumps are the products of the expertise gained from over four decades of experience, endurance and workmanship. OSWAL products are engineered to perfection with utmost care and stringent quality control at all stages to ensure a trouble free service.

OSWAL horizontal multistage centrifugal pumps are axial suction and vertical radial delivery with threaded ports. The impellers, diffusers and shaft of these pumps are made of stainless steel and designed to deliver the best possible hydraulic efficiency . This pump is a non-self priming horizontal centrifugal pump with mechanical shaft seal and sealing is by means of a bellows mechanical seal.

These pumps are powered by at any enclosed fan cooled A.C. induction motor , suitable for continuous duty . Motor stator is made of low watt loss steel laminations assembled under pressure and rigidly locked in the frame. Dynamically balanced rotor ensures vibration free and noise free operations. Shaft is made of quality stainless steel. All single-phase pumps are incorporated

with thermal over load protector. These pumps require an adequate starter/motor protector control panel.

Applications :

Industrial and domestic water pressure boosting and distribution

Small farms

Pumping of clean liquids in industry

Car washing

Hotels & Multistory Buildings

Salient Features

Fitted with motor protector

SS304 Impellers and stage casings

Designed for wide voltage fluctuations

Aluminum body for better the heat dissipation

Higher working pressure

Sturdy and compact

| Specifications : | |

|---|---|

| Output | 0.22 " 5.5 KW / 0.3 " 7.5 HP |

| RPM (Pole ) | 2880 RPM / 2 Pole |

| Enclosures | TEFC |

| Frame | 71 |

| Ambient temperature / temperature rise | 55°C / 80° C |

| Insulation Class | F |

| Voltage | 220 V |

| Frequency | 50 Hz |

| Connection | Single Phase |

| Duty | S1 |

| Degree of protection | IP55 |

| Main Dimensions (mounting) | Foot Mount - 96 X 115 mm Suitable for 8 mm/10 mm Bolt |

| Pumped Liquids Thin, clean, non-aggressive and non-explosive liquids without solid particles or fibers. |

|

| Temperature | 45°C (max.) |

| Permissible amount of sand | 28 gm / m (max.) |

| Chlorine ion density | 500 ppm (max.) |

| Allowable solids | 3000 ppm (max.) |

| Specific gravity | 1.004 (max.) |

| Hardness (Drinking Water) | 300 (max.) |

| Viscosity | 1.75 x 10 m / Sec. (max.) |

| Turbidity | 50 ppm silica scale (max.) |

| pH | 6.5 to 8.5 |

| MATERIALS OF CONSTRUCTION | |

| Part Name | Type S |

| Pumps Casing | Cast Iron |

| Pump Bracket | Cast Iron |

| Impeller | SS-304 |

| Diffuser | SS-304 |

| Motor Frame | Aluminum |

| Shaft | SS-410 |

| Mechanical Seal | Carbon & Ceramic |

| Base Plate | Mild Steel |

| Performance Table 50Hz | OCM -1 | |||||||||||||||||

| MODEL | K.W. | H.P. | Stage | Discharge | ||||||||||||||

| M3/H (LPM) | 0 | 0.4 | 0.8 | 1 | 1.2 | 1.6 | 2 | |||||||||||

| LPM | 0 | 7 | 13 | 17 | 20 | 27 | 33 | |||||||||||

| OCM-1 | 0.22 | 0.3 | 3 | 27 | 26 | 25 | 23 | 22 | 19 | 15 | ||||||||

| OCM-1 | 0.3 | 0.4 | 4 | 36 | 35 | 33 | 31 | 29 | 26 | 20 | ||||||||

| OCM-1 | 0.37 | 0.5 | 5 | 45 | 44 | 41 | 39 | 36 | 32 | 26 | ||||||||

| OCM-1 | 0.45 | 0.6 | 6 | 54 | 53 | 49 | 47 | 44 | 38 | 31 | ||||||||

| Performance Table 50Hz | OCM - 2 | |||||||||||||||||

| MODEL | K.W. | H.P. | Stage | Discharge | ||||||||||||||

| M3/H | 0 | 0.8 | 1.6 | 2.5 | 3 | 3.5 | 4 | |||||||||||

| LPM | 0 | 13 | 27 | 42 | 50 | 58 | 67 | |||||||||||

| OCM- 2 | 0.22 | 0.3 | 2 | (HEAD (METERS) | 18 | 17 | 15 | 13 | 10 | 8 | 6 | |||||||

| OCM- 2 | 0.3 | 0.4 | 3 | 27 | 26 | 23 | 19 | 15 | 13 | 9 | ||||||||

| OCM- 2 | 0.37 | 0.5 | 4 | 36 | 34 | 30 | 25 | 20 | 17 | 12 | ||||||||

| OCM- 2 | 0.45 | 0.6 | 5 | 45 | 43 | 38 | 32 | 25 | 21 | 15 | ||||||||

| OCM- 2 | 0.55 |

|

6 | 54 | 51 | 45 | 38 | 30 | 25 | 18 | ||||||||

| Performance Table 50Hz | OCM-3 | ||||||||||||||

| MODEL | K.W. | H.P. | Stage | Discharge | |||||||||||

| M3/H | 0 | 0.8 | 1.6 | 2.4 | 3 | 3.6 | 4.2 | ||||||||

| LPM | 0 | 13 | 27 | 40 | 50 | 60 | 70 | ||||||||

| OCM 3 | 0.37 | 0.5 | 3 | 28 | 27 | 26 | 24 | 21 | 18 | 14 | |||||

| OCM 3 | 0.45 | 0.6 | 4 | 37 | 36 | 34 | 31 | 29 | 25 | 19 | |||||

| OCM 3 | 0.55 | 0.75 | 5 | 46 | 45 | 43 | 39 | 36 | 31 | 24 | |||||

| OCM 3 | 0.75 | 1 | 6 | 55 | 54 | 51 | 47 | 43 | 37 | 29 | |||||

| Performance Table 50Hz | OCM - 5 |

||||||||||||||

| MODEL | K.W. |

|

Stage | Discharge | |||||||||||

| M3/H | 0 | 2 | 4 | 6 | 7 | 8 | 9 | ||||||||

| LPM | 0 | 33 | 66 | 100 | 117 | 133 | 150 | ||||||||

| OCM 5 | 0.3 | 0.4 | 2 | (HEAD (METERS) | 18 | 15 | 13 | 11 | 9 | 6 | 4 | ||||

| OCM 5 | 0.45 | 0.6 | 3 | 27 | 23 | 20 | 16 | 13 | 10 | 6 | |||||

| OCM 5 | 0.55 | 0.75 | 4 | 36 | 31 | 26 | 21 | 18 | 13 | 8 | |||||

| OCM 5 | 0.75 | 1 | 5 | 45 | 39 | 33 | 27 | 22 | 16 | 10 | |||||

| OCM 5 | 1.1 | 1.5 | 6 | 54 | 46 | 40 | 32 | 26 | 19 | 12 | |||||

| Performance Table 50Hz | OCM - 10 | |||||||||||||||||

| MODEL | K.W. | H.P. | Stage | Discharge | ||||||||||||||

| M3/H | 0 | 3 | 5 | 8 | 10 | 12 | 14 | |||||||||||

| LPM | 0 | 50 | 83 | 133 | 167 | 200 | 233 | |||||||||||

| OCM10 | 0.75 | 1 | 1 | (HEAD (METERS) | 16 | 15 | 14 | 14.5 | 13 | 11 | 9 | |||||||

| OCM10 | 1.5 | 2 | 2 | 31 | 31 | 28 | 28 | 26 | 23 | 18 | ||||||||

| OCM10 | 2.2 | 3 | 3 | 47 | 46 | 43 | 43 | 39 | 34 | 28 | ||||||||

| OCM10 | 3 | 4 | 4 | 62 | 61 | 57 | 57 | 52 | 46 | 37 | ||||||||

| OCM10 | 3.7 | 5 | 5 | 78 | 77 | 71 | 71 | 65 | 57 | 46 | ||||||||

| Performance Table 50Hz | OCM - 15 | |||||||||||||||||

| MODEL | K.W. | H.P. | Stage | Discharge | ||||||||||||||

| M3/H | 0 | 4 | 8 | 12 | 15 | 18 | 20 | |||||||||||

| LPM | 0 | 167 | 200 | 234 | 267 | 300 | 334 | |||||||||||

| OCM15 | 1.5 | 2 | 1 | (HEAD (METERS) | 17 | 16.5 | 16 | 15.5 | 15 | 13 | 11 | |||||||

| OCM15 | 2.2 | 3 | 2 | 33 | 32.5 | 32 | 31 | 30 | 27 | 22 | ||||||||

| OCM15 | 4 | 5.5 | 3 | 50 | 49 | 47 | 46 | 45 | 40 | 33 | ||||||||

| OCM15 | 5.5 | 7.5 | 4 | 66 | 65 | 63 | 62 | 60 | 53 | 44 | ||||||||