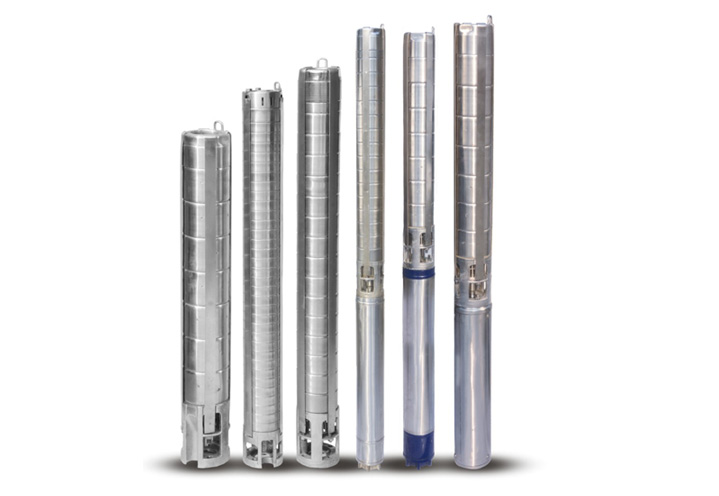

V4 Stainless Steel Borewell Submersible Pumps (Oil Filled) 100mm

OSWAL submersible pumps & motors are well known for its quality, Reliability & excellence for all type of service purpose. OSWAL submersible pumps & motors are manufactured under supervision of highly qualified technical team with a stage wise rigid inspection procedure under TQM concepts.

Application of Bore well submersible pumps are in Hospitals, Water circulation systems, Water supply systems of Government, Irrigation, Farms & Drip & sprinkler irrigation, Gardening, Nurseries, Domestic water supply, Multi-storey Building, Industries & Hotels.

Manufactured by stainless steel fabricated technology, pumps are energy efficient and cost efficient, light weight easy for handling, life longevity, corrosion free. Pump shaft using Duplex steel for high wear resistance. Fully fabricated S.S.-304 pump set is with quality level as per international standard and the same quality is supply in domestic market.

OSWAL Submesible Pumpsets of modular design is suitable for under-water operation for universal fit, all mounting dimensions of pumps and motors are in accordance with NEMA standards.

OSWAL Oil Filled pumps sets are highly efficient, low power consumption, complete absence of suction trouble. Maintenance free operation due to water lubricating bearings, vibration free & noiseless operation and world class design gives higher discharge & high efficiency. Easily repairable & dismountable.

OSWAL Oil Filled submersible motors are easily rewind able & repairable. Motor filled with food grade cooling oil. Oil filled motor consist of ball bearing to minimize the frictional losses & to increase the efficiency. Oil used as a coolant and work as lubricant in motor so life of motor is increases due to less wear & tear. The basic function of coolant is to lubricant bearing of rotor, removing heat generated in motor and oil is working as a coolant for smooth operation of pump.

OSWAL BORE WELL SUBMERSIBLE PUMP confirm to IS : 8034.

Mounting dimension of 4" pumps sets are as per NEMA standard

| Specification | ||

| OSP-2,3,5,8 & 14 Series | ||

| Power Range & Version | 0.5 HP - 5.0 HP 1 Phase 0.5-7.5 HP in 3 Phase |

|

| Version | 220-240V, 50 Hz,A.C. 1Phase 350-440V-3 phase |

|

| Speed | 2880 rpm. | |

| Discharge Range | 23-250 in 1 Phase 23 -250 in 3 Phase |

|

| Head Range | 42-250 mtr in 1 Phase 42-350 mtr in 3 Phase |

|

| Outlet size | 25,32,40 & 50 mm | |

| Degree of Protection | IP 68 | |

| Maximum Outer diameter | 98 mm | |

| Duty | S1 (Continuous) | |

| Method of starting | Capacitor star and capacitor run (CSCR) in water filled Capacitor start and run (CSR) in oil filled In 1 Phase / DOL in 3 Phase |

|

| Mounting | As per Nema | |

| Material of Construction Pump | ||

| NRV Housing | Stainless Steel | |

| Check Valve | Stainless Steel | |

| Check Valve sheet | NBR | |

| Impeller | Stainless Steel | |

| Pump Shaft | Stainless Steel | |

| Pump Shaft | SS - 431 | |

| Suction inter Connector | Stainless Steel | |

| Coupling | SS 410 | |

| Material of Construction Motor | ||

| Upper, Lower Housing & Motor Base | Cast Iron (Regular) / Stainless Steel | |

| Stator Body | Cast Iron | |

| Shaft | Stainless Steel | |

| Bearing | Leaded Bronze in water filled Anti frictional deep groove ball bearing in oil filled | |

| Thrust Bearing Set | Carbon V/s SS in water filled | |

| Application in : • Water supply from bore well • AC and solar energy compatible • Municipal & Irrigation purpose • Water supply in commercial establishments • Small farms, gardening & nurseries. |

||